Higher production output and fleet optimization at Premix Concrete in Australia

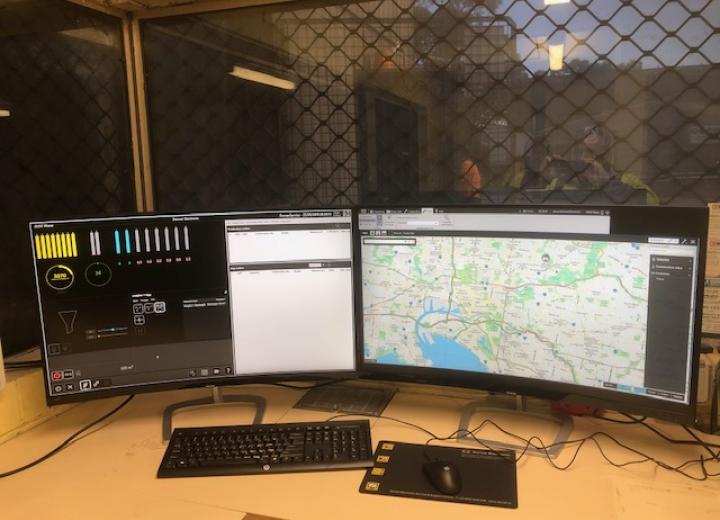

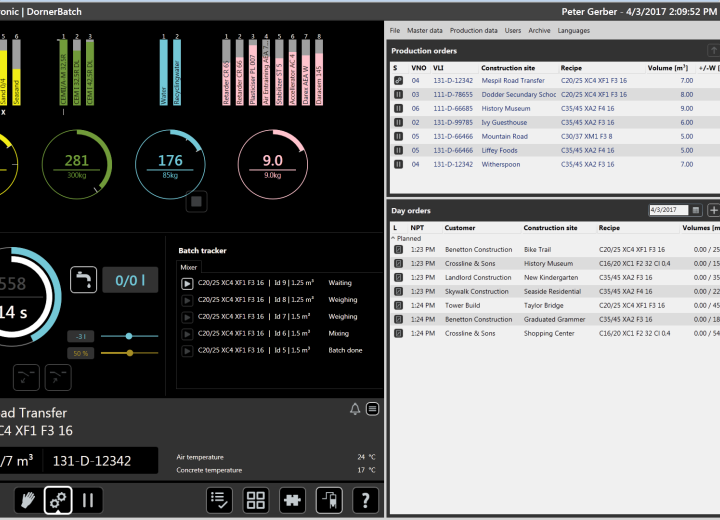

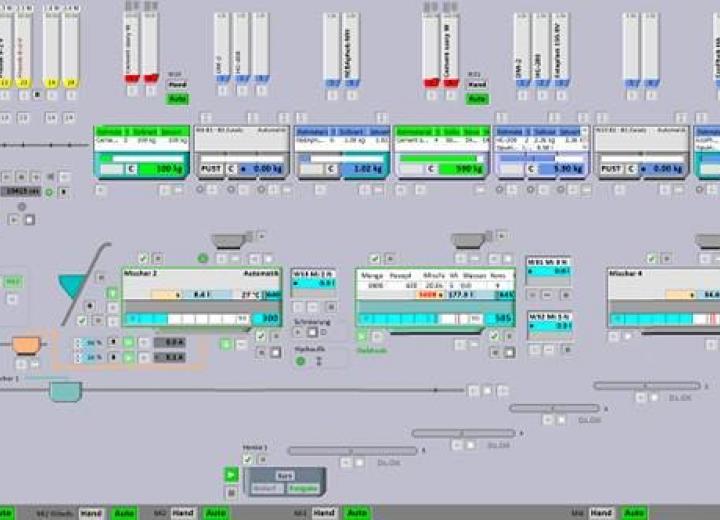

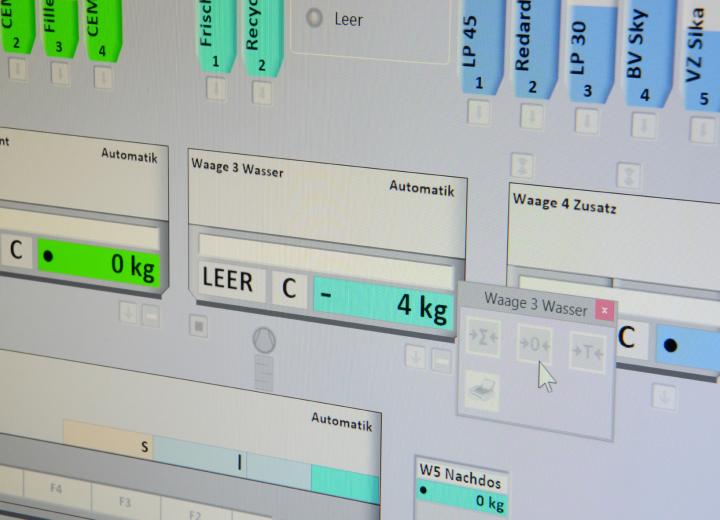

Premix Concrete SA is a locally run family business. The company specialises in architectural concrete in South Australia and operates three concrete plants as well as a fleet of 30 concrete trucks. Premix Concrete intended to use dornerOptimize - the disposition program of Dorner Electronic - to improve the utilization of plant and truck capacity and increase production output through improved batching systems. The company also decided to migrate all its plants to dornerBatch - the control software of Dorner Electronic. Installation and commissioning were always carried out on weekends to ensure minimal production interruptions during the transition.

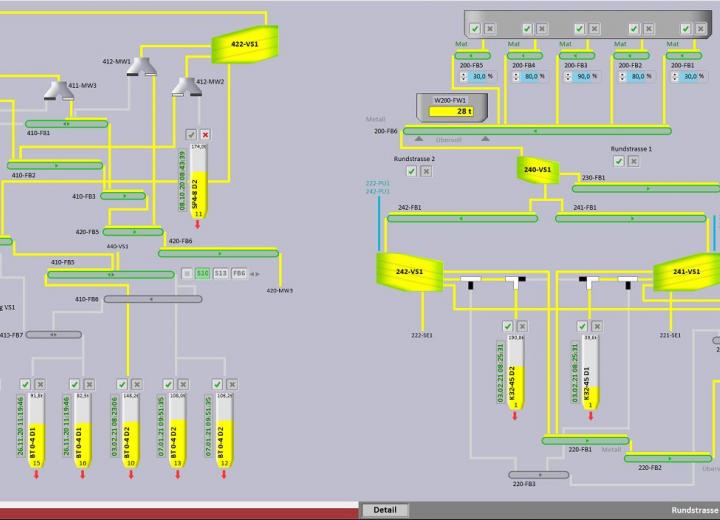

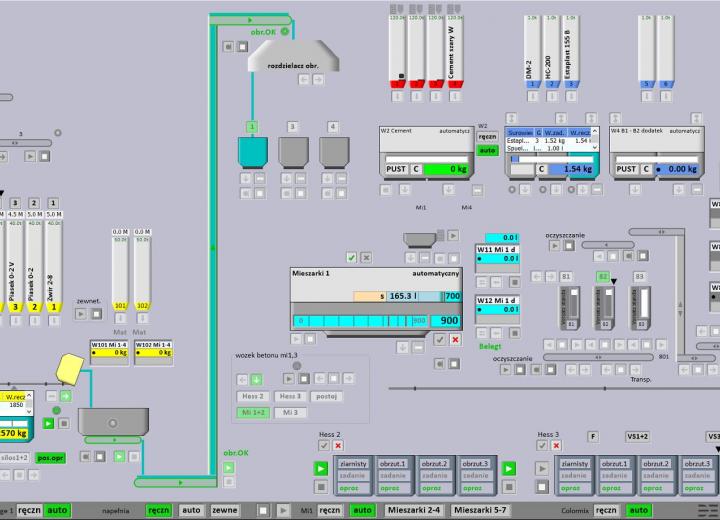

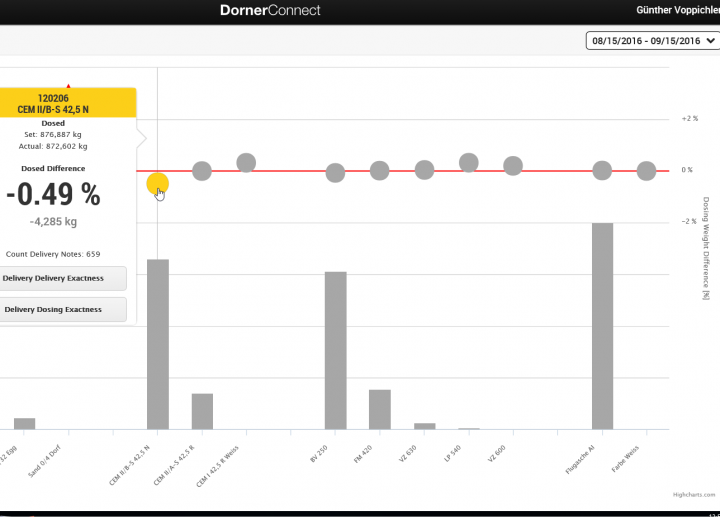

With dornerBatch, the production and dosing accuracy in their plants could be increased thanks to an easy-to-use interface, which enabled the operators to quickly familiarize themselves with the new system and get used to it. Technical Manager Luke Curran worked closely with the Dorner Service Team to ensure the specific requirements of the project and meet installation deadlines. “We began to see instant improvements throughout all plants when dornerBatch was installed. At our main plant in Salisbury, originally, we were weighing up 7m³ in 40 seconds, this has been significantly reduced to 4 seconds. Production output, scheduling and utilisation of fleet and staff has all been improved. Ryan O’Connor and his team have performed extremely well to ensure no lost time with our production schedule during the installation and commissioning process. We are looking forward to building on our relationship with Dorner.”, says Luke Curran.