Textile concrete - lightweight, load-bearing and sustainable

In order to enhance the sustainability of the material and to reduce the minimum thickness of the structural elements, a possible approach is to reinforce concrete with stainless steel and/or non-metallic reinforcement. This allows not only for a more rational use of the material, but also to reduce the needs of clinker.

Advantages

- the reinforcement doesn't rust

- significantly higher tensile strength than steel

- the interaction of slender components with low dead weight and high load-bearing capacity permits filigree components and shell structures

- best mechanical properties

- retain their strength despite aging

Composition

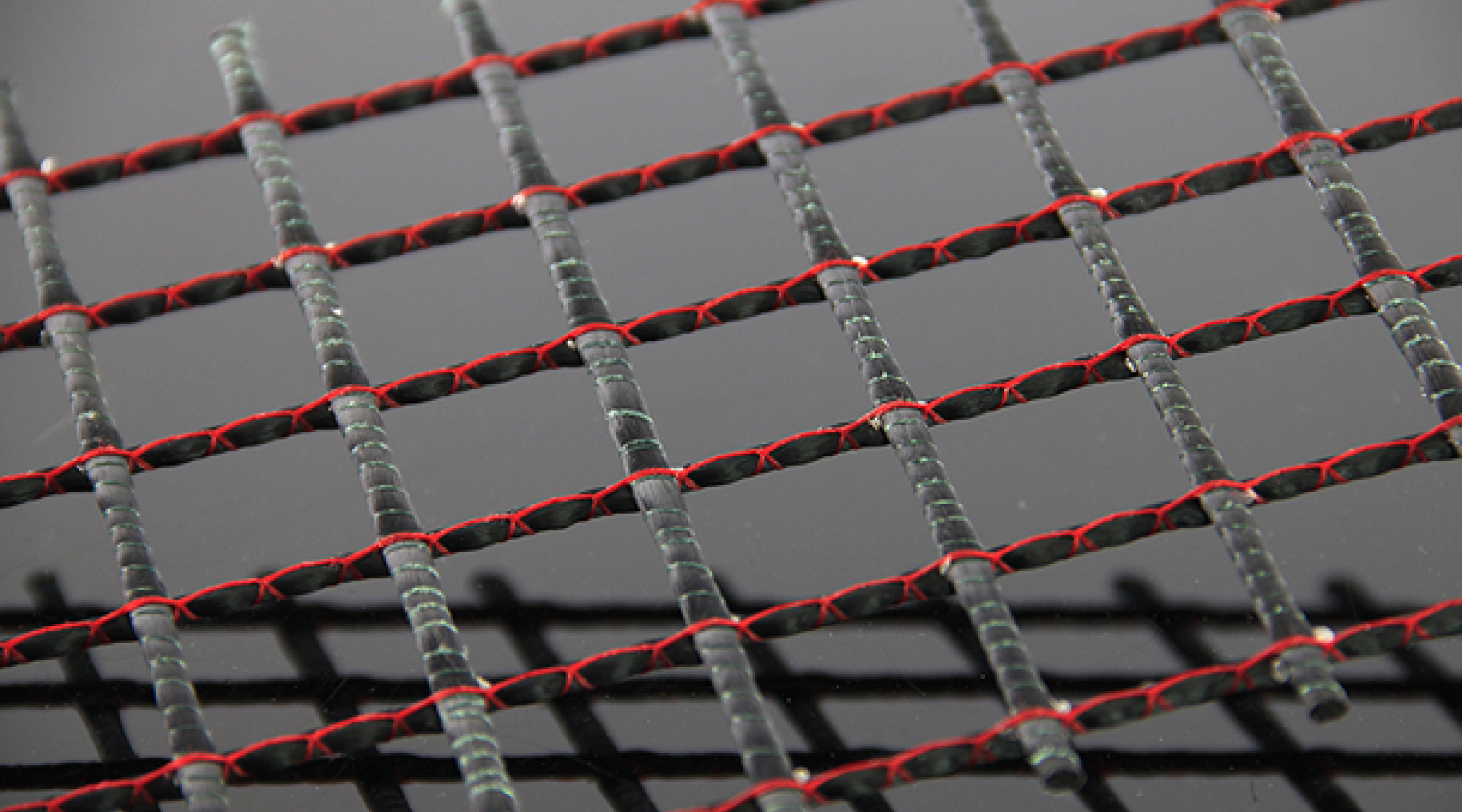

- fine concrete matrix and high-performance carbon fiber materials

- alkali resistant glass (AR glass) or basalt

Use

- in bridge construction

- in the construction of shells for roofs

- in the production of façade elements and in the repair

According to previous experiences, TRC can be casted in low thicknesses (typically 1 – 5 cm) with satisfactory mechanical and durability properties. These experiences have shown that the use of thin-walled cross sections with considerably high reinforcement ratios require the use of fluid mortars. As a result, cementitious matrices with a fine grained structure are used, that can usually be associated with high mechanical performances (they are for instance also used for ultra-high performance fibre-reinforced concrete). This will be the approach followed within this research, although some potential for improvement will also be highlighted.